Filter Dryer Systems

The Trusted Specialist in Solid Liquid Separation

PSL is a centre of engineering excellence in the design and manufacture of filter dryer systems used in sectors such as pharmaceuticals and fine chemicals. Our Agitated Nutsche Filter Dryers (ANFD) are renowned for their quality design and range from laboratory to pilot, up to commercial production.

PSL’s filtration and drying solutions help maintain your key process objectives of product quality, product yield, batch consistency and key production parameters such as filtration time, washing time, drying time etc. They have helped manufacturers around the world bring their products to market faster and overcome well-known production challenges faced when using traditional production methods such as Büchner filtration and oven tray-drying.

Our filter dryers provide optimum levels of safety and quality and can be manufactured to comply with various industry practices (cGMP, GAMP, etc.), directives (ATEX, etc.), regulations (21 CFR Part 11, etc.) and initiatives (PAT, etc.) from industry regulators such as the FDA.

Our Range

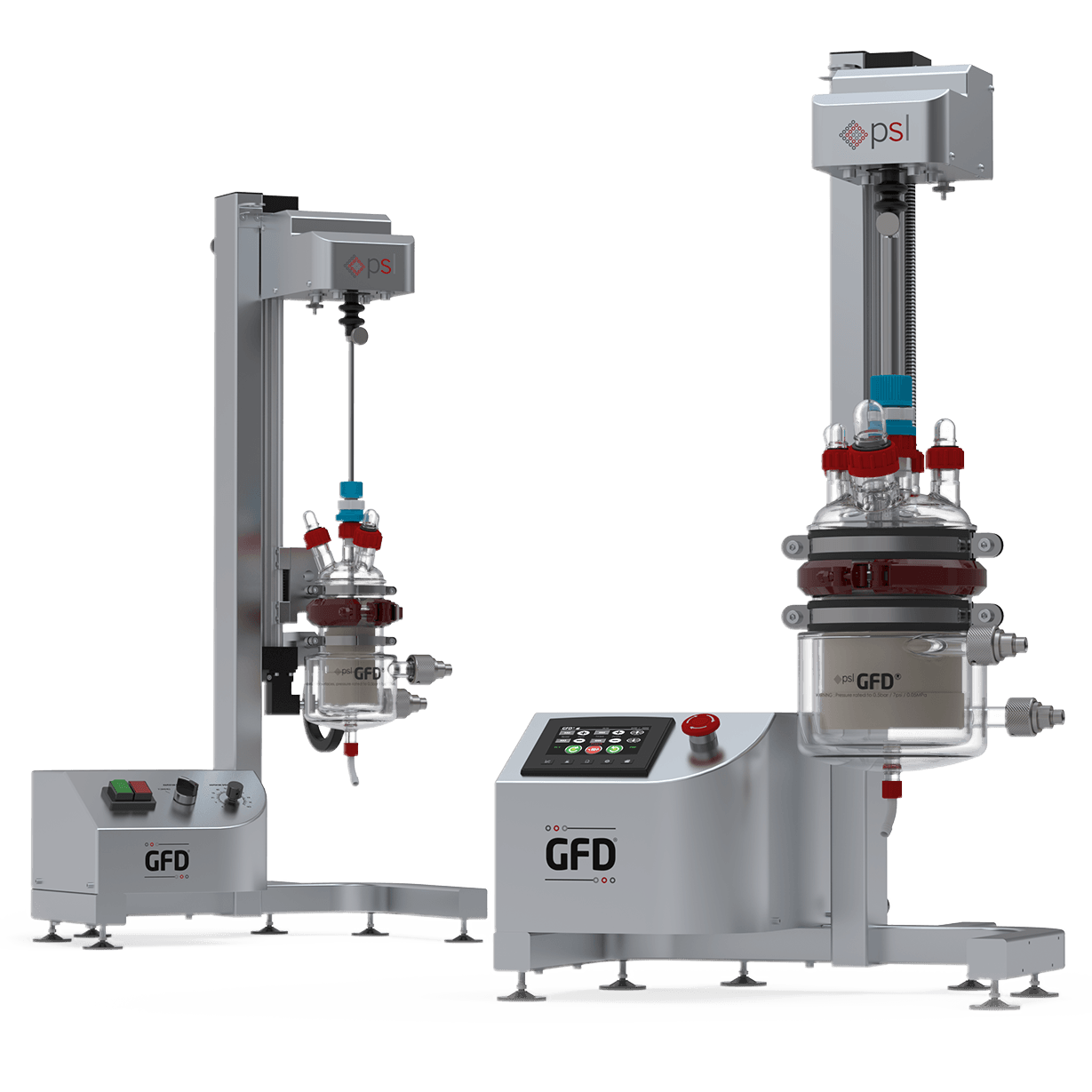

GFD®Lab

The GFD®Lab is a benchtop Agitated Nutsche Filter Dryer that efficiently performs laboratory solid-liquid separation processes. It is a miniature version of a production filter-dryer, allowing effective filtration and drying with the same reliability and benefits as full size PSL ANFD filter dryers.

GFD®Pilot

The GFD®Pilot is an Agitated Nutsche Filter Dryer that carries out solid-liquid separation processes at Kilolab and Pilot scale. It facilitates feasibility and proof of concept activities developed during smaller scale research and development stages and provides the opportunity to progress and refine operations.

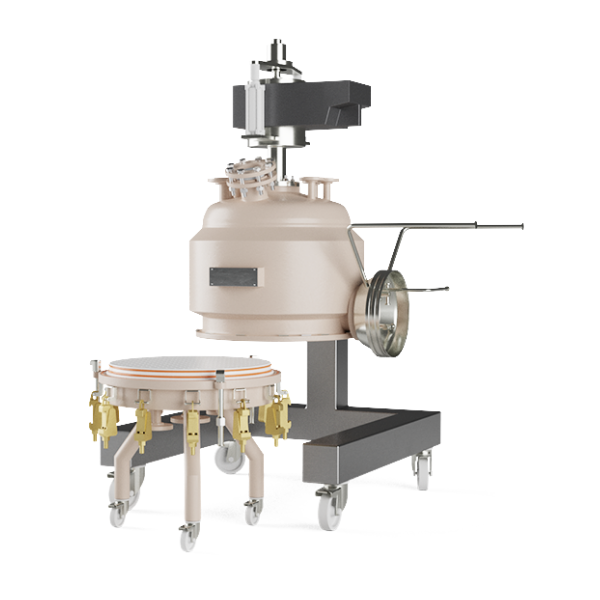

Agitated Nutsche Filter Dryers

PSL’s full size Agitated Nutsche Filter Dryers efficiently wash and isolate solids in the most complex chemical synthesis processes and challenging production environments. They are used in commercial production in a wide range of industries such as pharmaceuticals and fine chemicals for sensitive and/or high value products.

Agitated Nutsche Filter Dryers

A filter dryer combines two processing steps within a single piece of equipment. Firstly, solid-liquid separation is carried out, also known as filtration. The second step often consists of washing the product for removing impurities and/or solvent traces. The final step is to dry the collected solids.

In the majority of cases the solid is the product of interest but filter dryer technology can also be used in processes where the filtrate (liquid) is the valuable product. It is also possible to retain both the solid and the filtrate, if required.

Key Components of a Filter Dryer

- A fully sealed vessel which can be pressurised or put under vacuum.

- A bi-directional agitator within the vessel with a height-adjustable blade to account for variable product cake thicknesses.

- A filtering element at the base of the vessel, usually mesh.

- Temperature controlled zones including heated jackets and in some cases a heated agitator.

Enhanced Functionality

The Agitator within Nutsche Filter Dryers provides superior performance over traditional methods such as Buchner Filtration and Tray Dryers by offering the following features.

- Preventing heavy build-up on the filtration screen by keeping the product in motion in order to keep a rapid filtration rate.

- Maintaining efficient pressure filtration by smoothing the top surface of the wet cake.

- Providing homogenous drying throughout the batch by gently mixing (ploughing) powder.

Unrivalled Containment Expertise

As an early pioneer of containment technology, PSL enhances its filtration and drying solutions with unique high-containment systems.

Many industrial filtration and drying processes require integrated containment technology in order to protect operators from highly toxic compounds and/or to protect sensitive products from the production environment. PSL containment systems can be integrated to allow end-users to complete a large range of process operations such as product sampling and product discharge while protecting the product integrity and maximising product yield.

PSL offer a range of containment solutions for integration with our filter dryers. Selection is based on the containment performance requirement and/or organisational preference for either rigid containment or flexible/disposable solutions.