Process Solutions

PSL’s solid liquid processing expertise is fundamental to our success in providing innovative filtration and drying solutions. Our products are used worldwide, in a variety of sectors and are underpinned by our commitment to ongoing innovation, quality and customer service excellence.

Our products are grouped into 3 distinct categories; Microsphere Formulation, Filter Dryer Systems, and Vacuum Tray Dryers.

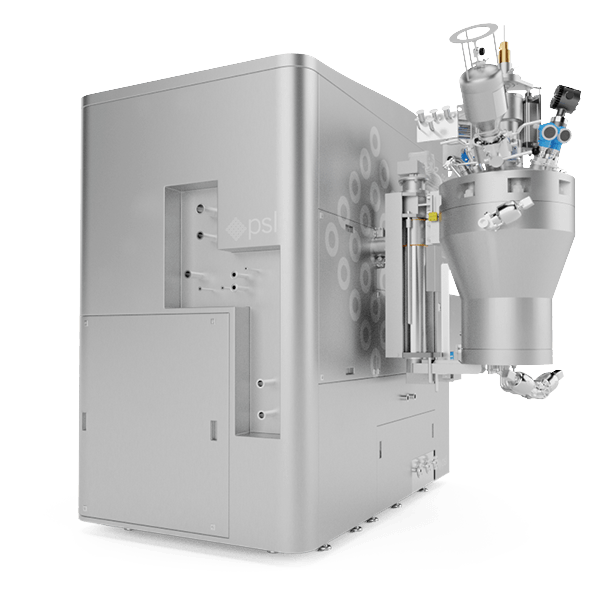

Microsphere Formulation

Decades of experience in aseptic manufacturing has led PSL to develop the unique MicroSphere Refiner range for efficient microsphere formulation from small-scale processes up to commercial production. Polymeric microspheres are ideal vehicles for many controlled delivery applications due to their ability to encapsulate a variety of drugs, biocompatibility, high bioavailability and sustained drug release characteristics.

Our process experts developed this innovative technology to address ongoing manufacturing challenges encountered by professionals working on synthetic polymers (PLGA, PEG, Hydrogel, etc.) such as size classification, efficient filtration (no mesh blocking), homogeneous drying, aseptic recovery of product and direct process scale-up.

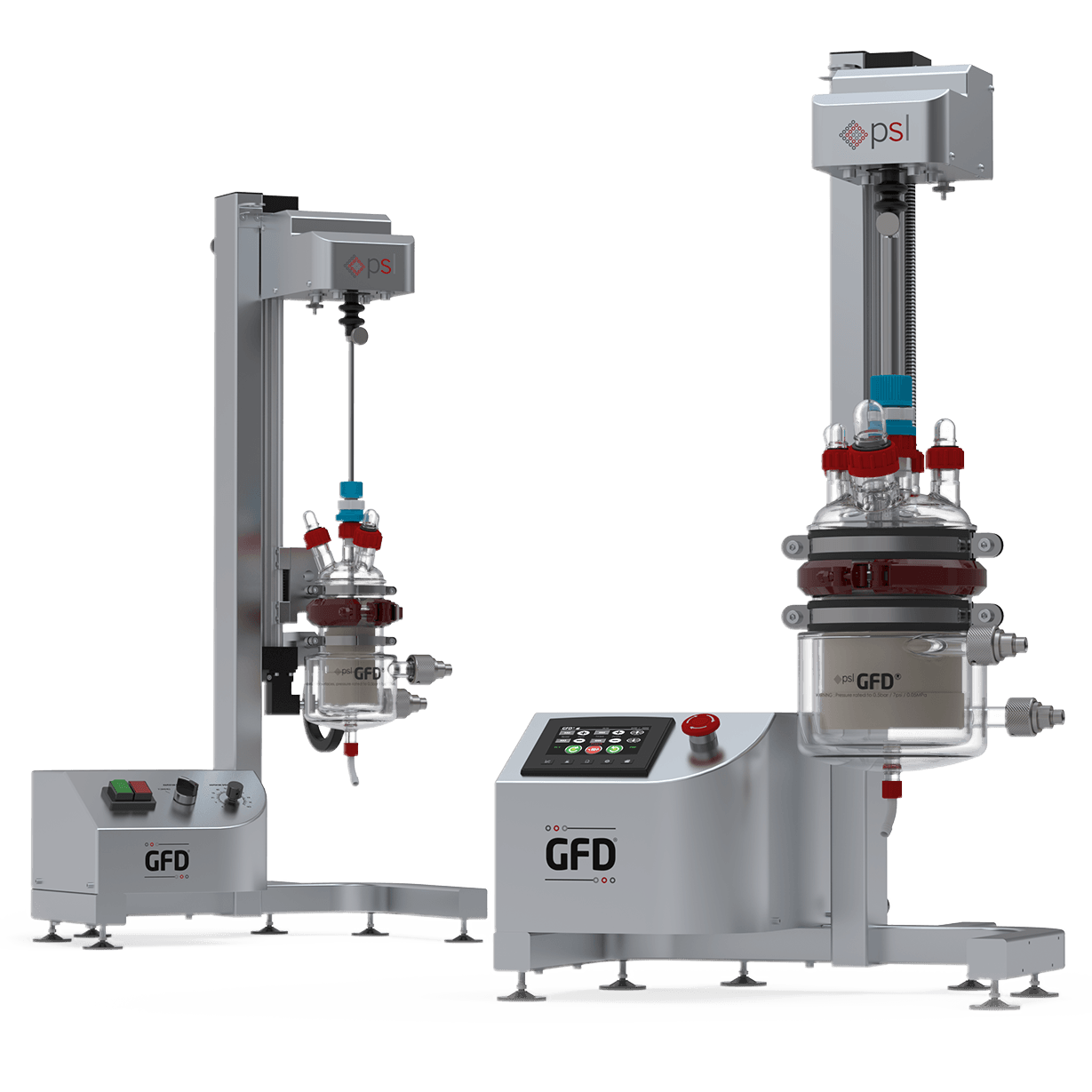

Filter Dryer Systems

PSL is a centre of engineering excellence in the design and manufacture of filter dryers from small-scale process development to large-scale manufacturing. PSL’s Nutsche Filter Dryers are internationally renowned for their efficient and quality designs developed for washing and isolating solids, even in the most difficult production processes.

Our range of filter dryers comprise of a number of ergonomically designed filtration and drying solutions, with or without integrated containment systems. Our engineering team and process experts draw on their experience to provide a full range of Agitated Nutsche Filter Dryers (ANFD) including standard filtration and drying equipment.

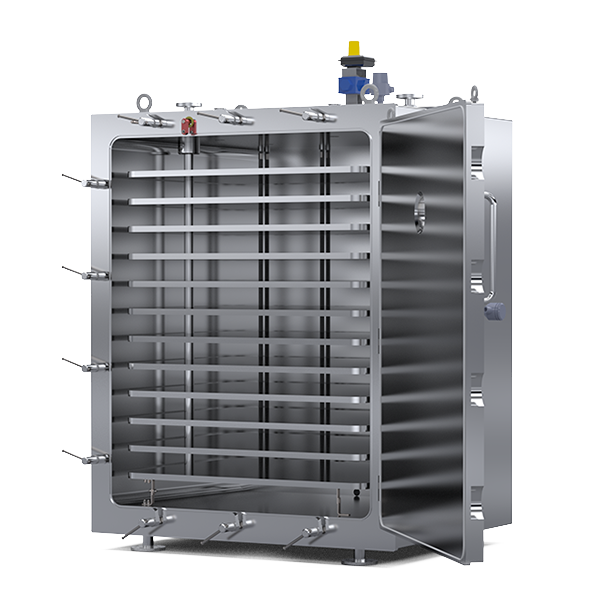

Vacuum Tray Dryers

Vacuum tray dryer technology is suited to various industries but is predominantly used for pharmaceutical processes and products. This static drying equipment is utilised where materials are heat sensitive, delicate and/or fragile.

PSL’s vacuum tray dryer is cGMP compliant and engineered to address these conditions, providing heat uniformity, batch reproducibility and data recording with an optional software and automation package. Due to the manual loading and unloading of product trays, in the case of moving potent and/or toxic products, PSL have several containment options that be can be employed, depending on the product classification.