Vacuum Tray Drying made Easy

Although more advanced drying methods have been developed in the pharmaceutical industry, vacuum tray dryer technology remains an essential method with processes/products that are delicate or fragile when exposed to mechanical forces.

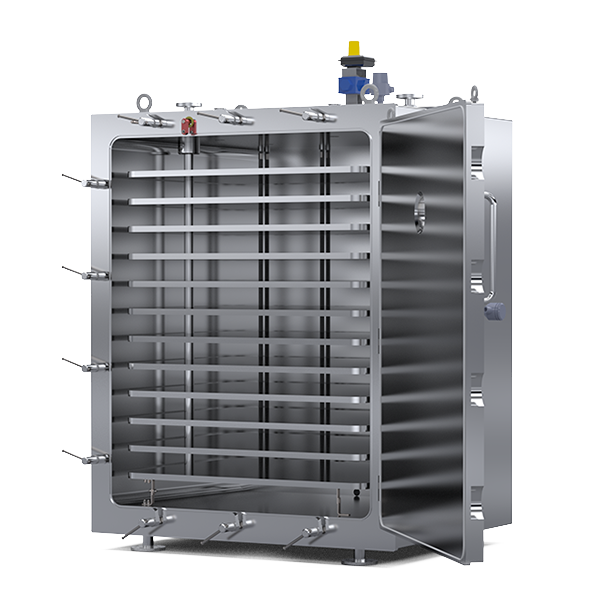

Our CakeStand™ vacuum tray dryer technology relies on a fully sealed vacuum chamber and direct heating shelves for optimum drying conditions and uniformity.

PSL tray dryers can operate in downflow booths, clean rooms or in conjunction with PSL containment isolators. A number of design features have also been incorporated into CakeStand™ for ease of use and product protection.

Features and Benefits

An All-In-One Solution

With drying uniformity being critical to a consistent high-quality end-product, PSL’s CakeStand™ Tray Dryers feature a vacuum chamber combined with direct heated shelves – with validated uniform heating of +/-1°C across the shelves – to ensure you meet even your most stringent batch processing requirements.

cGMP Design

Initially designed for the pharmaceutical industry, our Cakestand™ Tray Dryers carry features which comply with cGMP.

Batch Reproducibility & Data Recording

Our Cakestand™ Tray Dryers can be provided as stand-alone equipment for client/third-party integration or in combination with a Software and Automation package.

The PSL Automation Platform allows drug manufacturers to pre-design and also pre-load software process recipes incorporating the relevant process parameters suitable for their specific production requirements, hence adding speed and flexibility to their manufacturing processes.

PSL can comply with major international practices and regulations for Software Automation, including GAMP5 (Good Automated Manufacturing Practice, version 5 by ISPE) and 21 CFR Part 11 established by the US FDA for electronic records and signatures.

Be Containment-ready

Although the drying phase within a Vacuum Tray Dryer will require no physical operator intervention, the loading and unloading of the product trays remains manual. If the product is potent/toxic as it is often the case within pharmaceutical applications with API or HPAPI, these steps need to be contained.

Several containment measures can apply depending on the product classification and our Cakestand™ Tray Dryers are versatile enough to be integrated with most of them: