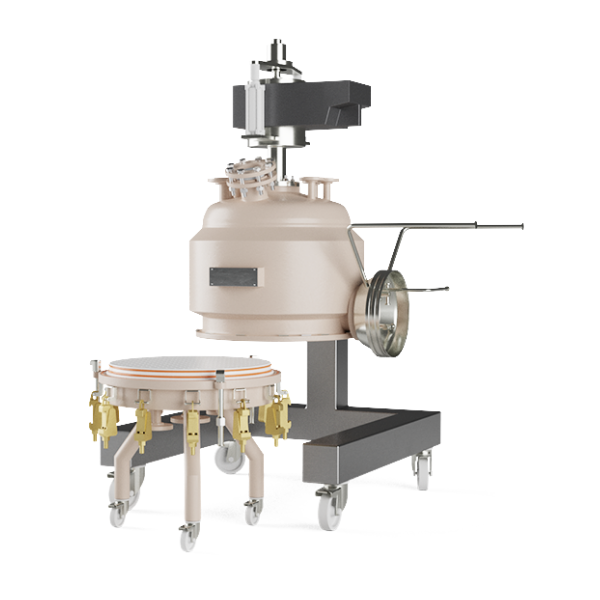

SimpleFilter™ : Nutsche Filter Dryer System

Solid Liquid Separation has never been Simpler

The SimpleFilter™ is a cost-effective and user-friendly solution allowing efficient Nutsche filtration and drying of small and pilot scale batches. It is a compact and mobile system that can be easily moved throughout different production areas within the same facility.

The SimpleFilter™ was developed to overcome well-known production challenges faced by manufacturers when using traditional production methods such as Büchner filtration and oven tray-drying. It is the ideal technology to successfully complete scale-up and scale-down activities and obtain predictive performance results.

The SimpleFilter™ consists of a single plate pressure & vacuum filter-dryer vessel equipped with a glove-bag containment system allowing simple and effective product discharge under nitrogen purge. Its vessel is available in different materials hence suiting a broad range of chemical processes.

Features and Benefits

An All-In-One Solution

The SimpleFilter™ is designed to allow process developers and manufacturers to complete a wide range of processes into one single system, hence maximising production efficiency and reducing equipment footprint.

Improving Production Agility

The SimpleFilter™ is a GMP piece of equipment ideal for multi-product applications. It is designed to allow end-users to remain agile and to quickly adapt to changing production requirements.

| FILTRATION AGILITY | DRYING AGILITY | CLEANING AGILITY |

|---|---|---|

| One modular base design | Direct heat transfer with base | GMP design / reduced product traps |

| Quick filtration media change-over | Vertical side wall heating jacket | Suitable for Reflux cleaning |

| Suitable for cloth & metallic mesh | Agitator option for drying uniformity | CIP spray-ring option |

Maximising Your Product Recovery

At Powder Systems, we understand that selecting the right processing technology is critical to scale-up your process and ensure your ultimate production success. The core features of our SimpleFilter™ were designed keeping this crucial requirement in mind.

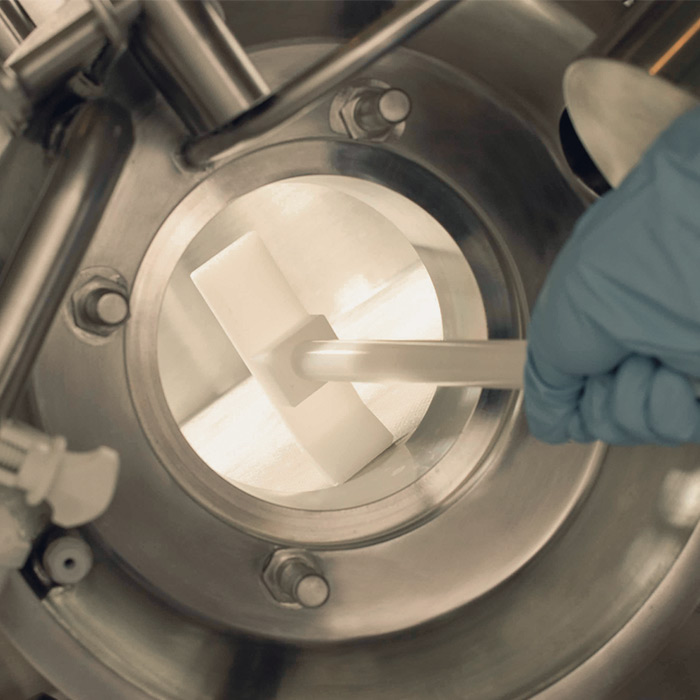

Upon batch completion inside the SimpleFilter™, your product can be easily collected by manually raking your batch from the vessel side-discharge into the glove-bag. If the agitator upgrade is purchased, the batch discharge process can be automated, with the final product heel removal only remaining manual.

Predictive Scale-Up Delivered

Our SimpleFilter™ product range was designed to streamline your scale-up development, from feasibility studies to pilot plant and commercial production. It the perfect tool to complete scale-up and scale-down studies as it will help you maintain – at every scale – your key process objectives (product quality, product yield, batch consistency, etc.) and key production parameters (filtration time, washing time, drying time, etc.).

Be Containment Ready

Being one of the early pioneers of containment technology, PSL has made all of its SimpleFilter™ models compatible with contained discharge technology.

The unique PSL glove-bag containment system was developed to allow end-users to perform safe product sampling and discharge within a nitrogen purge atmosphere for additional process safety and product integrity assurance.

Each flexible glove-bag is equipped with a 2-glove arrangement to enhance ergonomics and maximise product recovery by allowing product heel-removal. A tri-clamp connection is also provided to connect the glove-bag to the chosen discharge container (via continuous liner system, split-butterfly valve, etc.)